NOV GLASS REINFORCED EPOXY PIPING SYSTEMS

NOV FGS® is the market leader in the manufacture and supply of Glass fiber Reinforced Epoxy (GRE) piping – known under the trade name BONDSTRAND.

CAE has tremendous years in its chosen business. Today it is significantly active as an authorized distributor & approved installer for, NOV FGS® fiberglass reinforced pipes and fittings since year 2001 to covered Thailand, Cambodia and Myanmar territories.

OFFSHORE

Historically, offshore production platform, drilling rig and FPSO owners and operators have had to face the grim reality of continuously replacing most metal piping because of severe corrosion. This has resulted in piping systems costing two or three times the original investment since steel and metal pipe systems are very costly to maintain.

NOV FGS® GRE pipe systems are the cost-effective, maintenance-free and lightweight solution that provides corrosion-free and erosion-free operation during the service life of the vessel.

NOV FGS® GRE pipe systems are the cost-effective, maintenance-free and lightweight solution that provides corrosion-free and erosion-free operation during the service life of the vessel.

INDUSTRIAL & CHEMICAL

NOV FGS® is the combination of a series of product lines, bring- ing together over 60 years of “time-tested” composite pipe experi- ence to the Oilfield, Chemical/Industrial and Petroleum market. The broad range of temperatures, pressures and corrosion barriers allow for the best match between the product and these applica- tions.

Key Advantages

- GRE has a Price 25% Less than 6MO Steel

- GRE Reduces Operating Costs Due to Less Energy Needed to Pump Fluid Through the Smooth Internal Bore

- GRE is Corrosion-Free and Erosion-Free

- GRE is Easy and Cheaper to Install than Steel Systems

- GRE is Non Hazardous for the Environment and Personnel

- GRE is Easy to Repair

- GRE has Low Maintenance Costs

- GRE Reduces Amount Of Hot Work Wide Range of Industrial Applications

- Refinery

- Chemical & Industrial

- Power Plant

- Oilfield

- Pulp & Paper

- HVAC

- Water & Wastewater

- Food Processing

NOV GLASS REINFORCED EPOXY PIPING SYSTEMS

For over 65 years, Bondstrand™ has been a leading and trusted provider of corrosion-resistant, non-metallic composite solutions for marine and offshore, chemical, industrial, and mining project applica- tions. Combined with our unique range of engineering services, Bond- strand provides end users with versatile alternatives to traditional materials including glass-reinforced epoxy (GRE) piping, fiber-rein- forced polymer (FRP) structures, and composite pressure vessels.

This wide implementation is possible because with a Fiber Glass Systems composite solution, you receive the support and coverage of a global organization with a commitment to your success. With our Bondstrand product line, we're upholding a legacy of excellence as we continue to reduce your total cost of ownership

Our GRE and FRP products are lightweight, require minimal main- tenance, are highly durable and corrosion resistant, and are ideally suited to harsh environments, in particular marine and offshore appli- cations.

Bondstrand 2000 Series

Bondstrand 2000 is recommended for dilute acids and caustics, produced/hot water, industrial waste and condensate returns. Bond- strand 2000 piping system is designed and rated to meet require- ments of ASTM D2996 and ASTM D2310, meeting criteria for Type 1, Grade 1, Class F, National Sanitation Foundation Standard 61 (Drink-ing Water Components) and MIL-P-29206A for aviation fuel. Product recommended for hot water service, such as condensate return lines

Filament-wound pipe with Quick-Lock adhesive-bonding systems for close tolerance systems. Aromatic Amine cured epoxy for high toughness and temperature performance. A wide range of lined filament-wound (GRE) fittings are available.

Bondstrand 2400

Bondstrand 2400 is recommended for salt waters, brackish water, fi protection, potable/waste water and sewage, oil field reinjection, crude oil transmission and mild chemicals. Bondstrand 2400 piping system is designed and rated to meet require ments of API 15LR, ISO 14692 and ASTM D2310. Taper/Taper adhe sive bonded joint used for maximum pressure performance throughout product diameter and pressure range. Key-Lock mechanical joint can be used on pipe connections for ease and speed of assembly. Fittings in smaller diameters may be used over wide range of pressure classes

Filament-wound (GRE) pipe with an integral Taper female x shaved spigot adhesive bonded joint or Key-Lock integral female x male mechanical joint. Fittings are GRE with integral Taper female bell ends with a wide range available. Product line is well suited for higher pres- sure applications or where higher service factors are needed.

Bondstrand 4000

Bondstrand 4000 piping system is designed for aggressive chemic service where epoxy products are suited (solvents, alkalis and non-oxi dizing acids).

Bondstrand 4000 piping system is designed for aggressive chemic service where epoxy products are suited (solvents, alkalis and non-oxi dizing acids). Meets USFDA requirements for food processing u 21CFR175.105 and 21CFR177.2880. Quick-Lock joining system allo close tolerance fabrication of system.

Filament-wound (GRE) pipe with Quick-Lock adhesive-bonding sys tems for close tolerance systems. Aromatic Amine cured epoxy for hi toughness and temperature performance. A wide range of lined filament-wound (GRE) fittings are available

Bondstrand 5000

Bondstrand 5000 is available in 1”-16” diameters with temperat range up to 200°F (93°C). This is a custom Vinyl Ester pipe available Asia, Europe and South America and is recommended for most chl nated and acidic mixtures. Bondstrand 5000 is a custom vinyl es pipe available in Asia, Europe, and South America . It utilizes t Quick-Lock straight/taper adhesive-bonded joint featuring integral pi stop in bell for predictable, precise laying lengths. Vinylester re matrix recommended for oxidizing acid service and water purificati systems. Specialty resins can be used for services in excess of 200°F (93°C).

Filament-wound Glassfiber Reinforced Vinyl Ester (GRVE) pipe with Quick-Lock adhesive-bonding systems for close tolerance systems. Premium grade resins used for high temperature performance. A wide range of lined filament-wound (GRVE) fittings are available.

Bondstrand 7000

Bondstrand Series 7000 fiberglass pipe, fittings and flanges incorpo- rate high-strength conductive filaments to prevent accumulation and discharge of potentially dangerous levels of static electrical charges. Bondstrand 7000 piping system provides electrical conductivity to allow dissipation of electrical charge built up by flow of high-purity, non-conductive fluids, such as Jet Fuel. Unlined construction provided inside-to-outside as well as end-to-end conductivity with co-mingled carbon and glass fibers throughout the pipe wall. Suitable for primary piping within secondary containment (limited access) when connected to ground at discrete location.

Filament-wound (GRE) pipe with Quick-Lock adhesive-bonding sys- tems for close tolerance systems. Aromatic Amine cured epoxy for high toughness and temperature performance. Product designed to provide electrical conductivity to eliminate static electricity accumulation gen- provide electrical conductivity to eliminate static electricity accumulation generated by high purity fluids,

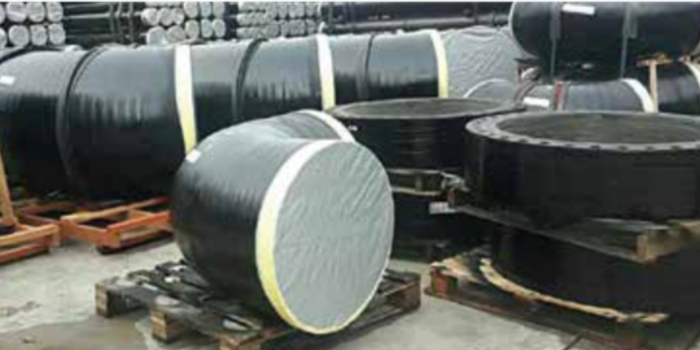

Our skids are custom built for each specific need and is durable and safe. Our manufacturing facility has the capacity to make the quantity and customized designed skids that your job requires. Our manufacturing process is proven and can produce your order in the volume that you need and when you will need it. There is no order that we can not fill. Our staff will sit down with you and review your specifications for your oil field needs

Skid Platform

CAE carry out the design fabrication and installation of prefabricated packaged process & utility skid mounted pumping systems for indus- trial heating cooling & heat recovery. Each prefabricated modular skid is designed specifically for individual customers requirements across a wide range of applications.

.jpg)