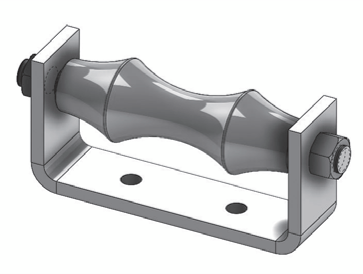

Pipe Supports Component

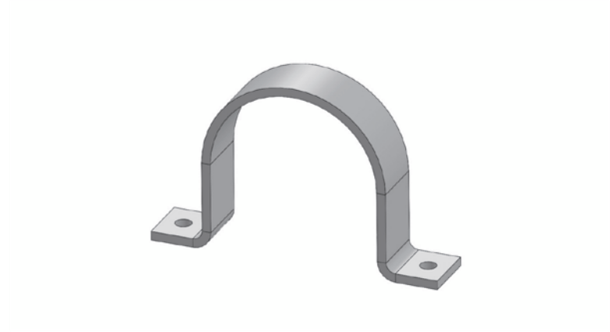

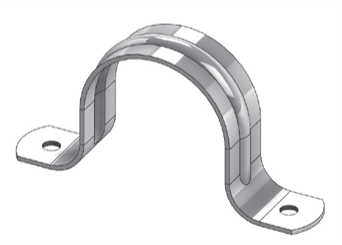

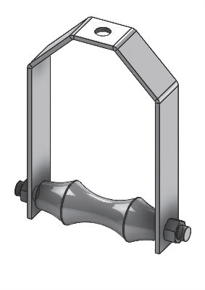

1. Support: Pipe Supports Bear The Weight Of The Pipes And Their Contents, Preventing Sagging, Bending, Or Damage Due To Excessive Stress. This Support Helps Maintain The Structural Integrity Of The Entire Piping System.

2. Alignment: Properly Designed And Installed Pipe Supports Ensure That Pipes Are Aligned Correctly. Proper Alignment Is Crucial For The Efficient Flow Of Fluids And To Prevent Strain On Pipe Connections And Fittings.

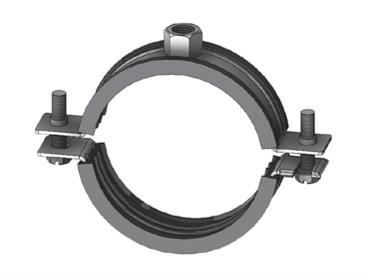

3. Vibration Control: Pipe Supports Can Incorporate Dampening Materials Or Mechanisms To Minimize Vibrations Caused By Fluid Flow Or Other Sources. Controlling Vibrations Helps Extend The Lifespan Of The Piping System And Reduces The Risk Of Damage.

4. Thermal Expansion And Contraction: Piping Systems Can Experience Thermal Expansion And Contraction Due To Temperature Changes. Pipe Supports Accommodate These Movements While Maintaining The Integrity Of The System

5. Protection: Supports Protect Pipes From Damage Due To External Forces, Such As Impact, Seismic Activity, Or Environmental Factors. They Can Also Prevent Contact Between Dissimilar Metals, Reducing The Risk Of Corrosion.

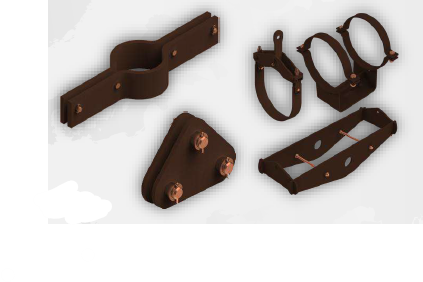

PIPE SUPPORTS

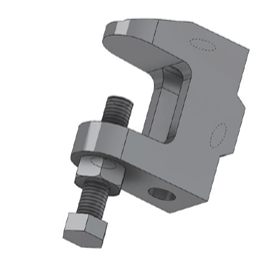

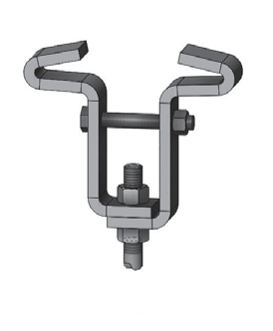

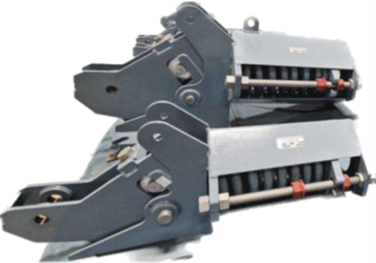

CONSTANT EFFORT SUPPORTS

Details of Vertical inverted tandem type (type VIT) are available on request. SUSPENSION STYLES For the suspended types. five styles of top suspension are available, namely S1, S2, S3 , S4 and S5 .

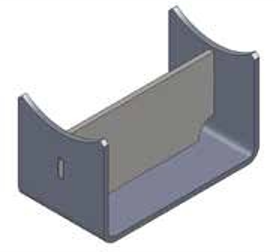

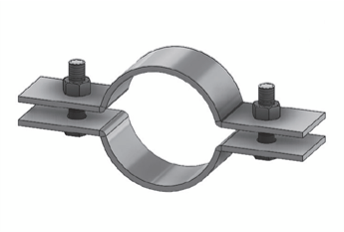

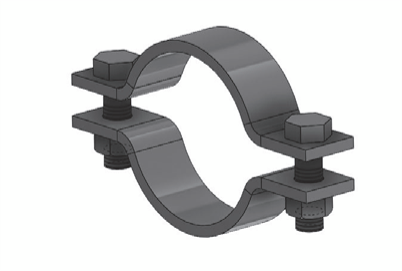

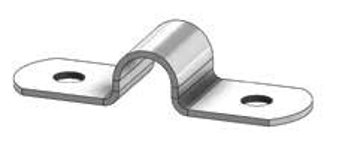

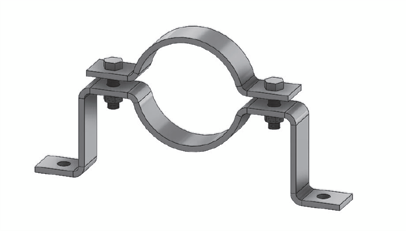

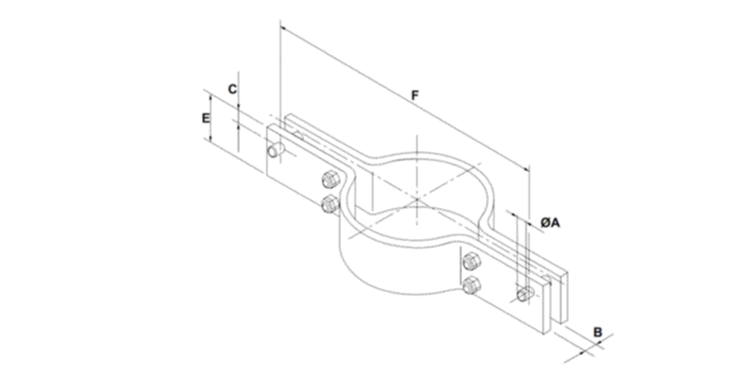

PA6 PRESSED RISER CLAMP SIX BOLT TYPE

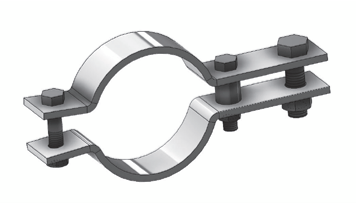

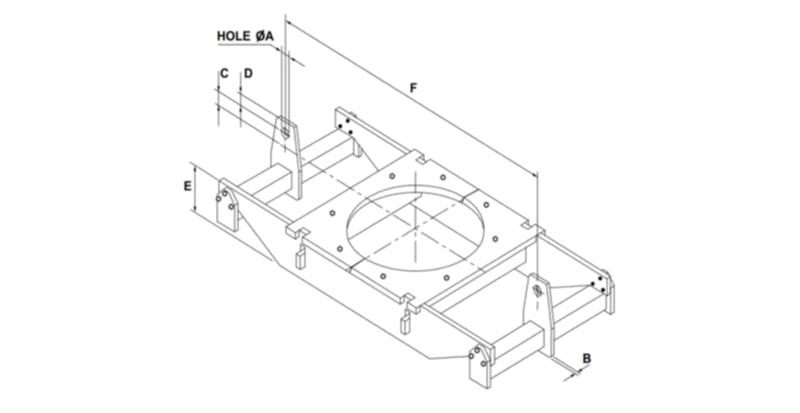

PA7 PA6 PRESSED RISER CLAMP FLAT PLATE TYPE

.jpg)