CAE Fabricators

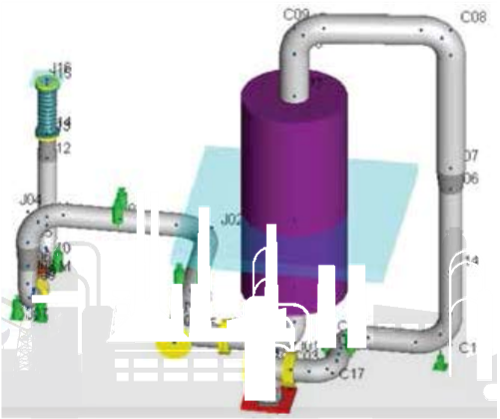

Whether you work in the oil and gas industry, a construc- tion trade, manufacturing, or transportation chances are you need a reputable company to provide durable piping support products.

Piping support fabrications are used to anchor, guide, sup- port, and absorb shocks from water hammer and other anomalies. Our piping support products not only help to extend the longevity of your pipes, but also prevent costly accidents that lead to work disruption and property damage.

High volume pipes are often under a considerable amount of weight and stress from not only the weight of the pipe materi- al itself, but also its contents. Support products secure pipes and transfer their weight and stress from the pipes to the support system. To fulfill your piping support needs, we fabri- cate the following types of piping support products:

-

Pipe supports

Pipe saddles

Pipe clamps

Pipe hangers

Pile caps

-

CAt CAE., we have the capabilities to provide you with any number of piping support products and pipe shoes. Our project managers have long relied on our products and expertise to provide proper support and weight distribution. Our pipe support products can be used in a number of applica- tions, such as oil and gas extraction, mining and much more

We take pride in offering pipe support products of the finest quality while also delivering services with the integrity and dedication our customers have come to expect

-

For a more detailed look at our pipe support products, or, if you have questions, or wish to discuss any work concerning pipe supports and pipe integrity, don’t hesitate to contact us.

Pipe Supports Inspection Services

A part of the piping system services CAE provide is the survey and assessment of support systems, known as hanger surveys. Whilst our work has focused historically on pipe support systems within the Power industry, assessing all Advanced Gas Reactors in the Thailand, this combination of on-site inspection and offsite assessment is some- thing equally applicable to other industries

Findings from these services provide the client with a clear view on the most cost effective solutions for maintaining pipework support sys- tems in a safe and working condition, minimizing repair costs and plant down-time over the life of the plant. Whether it’s power genera- tion, chemical, oil or gas, our highly trained experts can deliver high quality pipe support surveys.

What is a Pipe Hanger Survey ?

CAE conduct regular health surveys on the pipe support systems for the main steam and feed systems on all power stations in the Thai- land fleet. We refer to these as “Pipe hanger surveys” as the majority of supports are usually formed using long rods, or “hangers”, attached to civil structure steelwork high above the piping systems. These steam pipelines are often subject to significant thermal expan- sion and contraction due to the varying temperatures over which the plant operates. To accommodate associated vertical thermal move- ments, variable spring supports or, where movements are more signif- icant, constant load supports are used.

Maintaining the travel positions of these supports within their working range is essential for their correct function. The surveys undertaken aim to ensure that pipe supports of all types continue to provide effec- tive support maintaining the functionality and safety of their associat- ed piping systems.

The work we do aims to prevent such incidents as happened in 2006 at main steam line power station, where one hanger failed and subse- quently led to cascade failure of a large number of supports on a main steam line. Such incidents can result in costly plant damage and down- time, and in the worst case scenario, threaten industrial or nuclear safety.

CAE Pipe Hanger Survey Services

The work involves plant walkdown to physically inspect the condition of the pipework supports, recording travel positions and examining all load path components, considering potential defects such as;

- - End of travel reached – top/bottom

- - Gagged supports

- - Potential mechanism blockage due to debris or other objects

- - Broken or distorted components

- - Loose or missing nuts, bolts or locknuts

- - Misalignment

- - Interference/clashing with adjacent pipelines, supports, steelwork or equipment

- - Corrosion

- - Vibration

We review these observations in combination with historical move- ments, design movements, and where available, theoretical move- ments from pipework models. We will recommend remedial work to correct any defects or deficiencies we have observed

CAE Pipe Support Survey Services

Our surveys ensure that clients are provided with clear advice on main- tenance recommendations to ensure continued safety and reliability of the plant, reducing the risk of incidents potentially threatening safety, lost operation time, and higher maintenance or repair costs down the line.

Our longstanding relationship with the operators of plant and our asso- ciated responsibilities for the inspection and support to maintenance of the steam and feed piping systems has given us a wealth of experience to deliver pipework support services to any number of industries.

Other Related Services

Other related services we offer in support of pipework system design, assessment and maintenance include:

- - Design of piping systems

- - Design of piping support systems

- - Pipework system modeling

- - Design code and fitness-for-purpose assessment of pipework sys- tems

- - Assessment of consequences of out-of-range supports (restriction totravel)

- - Single hanger failure assessments (prevention of cascade failure)

- - Flow accelerated corrosion (FAC) inspection support and assessment For a more detailed look at our pipe support services, Or, if you have questions about our hanger survey services, or wish to discuss any work concerning pipe supports and pipe integrity, don’t hesitate to con- tact us equipment

Pipe Stress Analysis

Pipework within power stations and other engineering structures are subject stresses and strains as part of the regular operating environ- ment. If the loading and environment to which the pipes are exposed is not properly understood and controlled, it can lead to materials becom- ing damaged and a possible loss of containment or pipework failure

Through the use of pipe stress analysis, piping systems are evaluated to identify stresses throughout the system, establishing whether the layout meets the criteria specified in the relevant design code. Pipe stress analysis is suitable for simple and complex designs, and consid- ers both static and dynamic loads. CAE has a wealth of experience of representing systems for the purposes of code compliance assess- ments, design, modification, and fitness for purpose assessments

Whether at a design stage, manufacture or when operating, assessing the stresses in piping, and the associated risks of failure, allows clients a clear view of material lifetime expectations and appropriate mainte- nance strategies to ensure the most cost-effective and efficient solu- tions.

What is pipe stress analysis ?

Pipe stress analysis investigates the loads arising from the combination of:

-

Dead-weight

Cold-pull

Dynamic effects

Thermal expansion

Wind and snow loading

and considers these against the requirements of a selected design code.

The interaction of these loads may be complex, and has implications upon the design of suitable arrangements for the pipework, its fittings

The interaction of these loads may be complex, and has implications upon the design of suitable arrangements for the pipework, its fittings and supports. Safe piping design avoids overstressing or overloading components, equipment and supports.

CAE’s particular experience in pipe stress analysis is in power plant and petrochemical systems, however our expertise would be beneficial for any piping system in which safe operation is of concern. Our service allows the integrity and safety of systems to be maintained from the design stage through to the system’s end of life. CAE’s pipe stress analysis services

From the initial stages of a project to delivering the final product, CAE ensure that all details are covered in our pipe stress analysis through on-site survey, clear communication with our client’s wider team, and the oversight of experienced CAE staff.

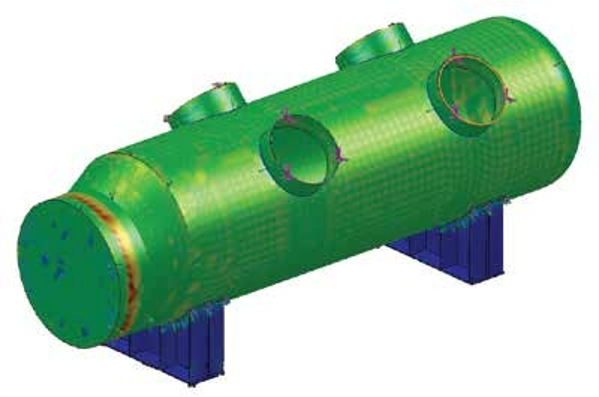

Finite Element Analysis

Finite element analysis is a service provided by CAE to offer clients quick, reliable results to complex problems

Whether it’s stress, thermal, seismic or strains on materials, Finite Element Modelling allows a solution that is more time efficient and economical than alternative experiments and calculations.

What is FEA?

Finite Element Analysis (FEA) is a computerized numerical method used to solve complex practical problems. These can range from predicting how a structure reacts to an applied force, vibration, heat, fluid flow to a multitude of other physical effects. FEA reaches an approximate solution to any complex engineering problem by discreti- zation of the geometry into manageable or finite elements which can be used to solve mechanical, thermal, magnetic or potential difference equations.

CAE FEA Services

CAE provides professional and reliable FEA consulting services ranging from concept design, development and maintenance of engineering components. The company has a proven track record of providing FEA consultancy services to clients in the power genera- tion, oil and gas and manufacturing industries

CAE engineers have degrees in various engineering fields and collectively have vast experience in engineering design using a vari-ety materials such as metal, concrete, plastic and elastomers.

Benefits of FEA include:

- - The ability to handle complex geometry and loading conditions.

- - Its application to areas such as structural, dynamics and heat transfer analysis.

- - Potential mechanism blockage due to debris or other objects

- - Safe simulation of potentially dangerous environments and failure modes impractical to test.

- - The ability to predict failure of real life structures subjected to a widerange of loading conditions.

- - Low cost solutions and rapid evaluation time for most applications.

We offer FEA consulting services to a wide range of areas including:

- - Stress Analysis

- - Heat Transfer Analysis

- - Seismic Analysis

- - Fatigue Analysis

- - Vibration Analysis

- - Impact Analysis

- - Cracked Body Analysis

CAE provides clients with professional FEA consulting services from designing new engineering concepts and optimizing existing compo- nents to extend their safe lifetime operation. We can offer clients FEA consulting services in accordance with the British, American and Euro- pean design codes with particular expertise in ASME III, PD5500, ASME B31.3, BS806, BS5950 and BS5400

Support our clients with reliable FEA simulation results allows an understanding and improvement to engineering designs, providing an efficient, cost-effective insight

If you have any further questions about FEA or you’d like to enquire about our services, or wish to discuss any work concerning, don’t hesi- tate to contact us.

CAE Scaffolding Installation Services

CAE extensive scaffolding range includes modular, tube, fitting and aluminium products. These are manufactured and maintained in accordance with the international standards for safety and reliability.

Our scaffolding systems are easy to assemble and have been manufactured with time efficiency and ease of use as paramount

In addition to the supply of scaffolding, we can also provide a professional and expert team for the supervision, management and installation of your systems and any subsequent services as required.

Installation and maintenance of hydraulic snubbers

Introduction

Hydraulic Shock absorbers are used primarily to prevent damage to piping systems and connected equipment in the event of earthquakes, flow induced vibration, pipe rupture/failure and relief valve activation. The snubber permits thermal expansion and contraction of piping systems but is designed to lock and protect the piping in the event of an upset scenario.

Typically, the snubber is set to lock at velocities greater than 2mm/s, though this figure can be refined in accordance with customer requirements. Each snubber is manufactured to customer requirements and briefly consists of the following:

- - Hydraulic tie-rod cylinder

- - Pressurized reservoir/accumulator

- - Valve manifold

- - Assembly extension tube

- - pherical bearing rod ends

The design of the Dynamic Support Systems pressurized reservoir and valve system permits the Snubber to be installed in any orientation.

In an upset scenario, if the velocity of the piston rod exceeds the pre-defined locking velocity, the valve system locks and the snubber accommodates the dynamic loads. The bypass system then activates,ensuring a controlled deactivation of the snubber unit. The snubber units and valves are calibrated at our works utilizing a state of the art test rig that measures locking velocity, bleed rate and the loads applied.. Adjustment of the u nits on site without consulting Dynamic Support Systems is strictly forbidden.

Installation

Prior to installation the snubber should be checked to ensure it has not been damaged during transit. The eye to eye dimension should also be checked and moved to the desired position if the piston has moved. Dynamic Support Systems utilize a centistoke polydimethylsiloxane silicone oil. This product offers excellent physical properties over a wide temperature range, however changes in ambient temperature may cause small movements of unit

the piston rod. If the piston rod does require adjustment, appreciation of the snubber function should be considered. Adjustment should be done slowly and steadily to prevent activation of the control block system and locking the snubber unit. On smaller units, twisting the piston rod will reduce friction within the unit and allow easier movement. If larger units (4"NB or greater) require adjustment, Dynamic Support Systems should be consulted.

If the piston is in the correct position but the eye to eye dimension is not suitable for the site requirement, adjustment can be made at the end of the extension tube. As standard snubber units have a +25mm adjustment facility.

Full installation instructions are available upon request and are attached to each unit prior to shipping.

Maintenance

Snubbers are installed throughout the world in various site conditions, and as such, maintenance requirements vary accordingly. Generally, the following procedure should be followed:

Internal, dust free environment, the following checks should be conducted annually. Check for oil leaks and oil deposits on the snubber

The piston rod is chrome plated to minimize friction through the seal system. It should be checked for abrasions and pitting that may lead to oil leaks. Check the oil level indicator pin on the pressurized reservoir..

External, heavy contamination - The same procedure above should be followed bi-annually.

Xylan

Xylan 1014

Xylan coating is a fluoropolymer coating that increases the life of fasteners and fastener components. This versatile coating addresses various engineering needs and solves surface property issues by providing a working surface tailored for the application. Xylan@ coatings are a composite material that come in a wide variety of formulas and colors. Each formulation offers unique performance properties that are extremely beneficial in aggressive environments and harsh conditions, such as the aerospace and oil and gas industries. This family of industrial coatings is also preferred by the engineering and construction industries, because they are easy to use, offer excellent versatility for use in a wide range of applications, and easily produced.

Xylan 1070

Xylan coated bolts, studs, screws, and other fastener types maintain their required dimensional tolerances while offering extraordinarily low coefficients of friction, excellent corrosion protection, and good chemical resistance. For example, Xylan@ coated fasteners are used to protect valves, pumps, and hydraulic systems in the oil and gas and chemical-producing industries. It also offers excellent lubricity to reduce friction, prevent wear and galling, and provide additional lubrication in high-load, high-pressure applications. Also, it is flame retardant, which makes it extremely useful in high-temperature applications.

Xylan 1424

Xylan coated fasteners offer the following benefits and advantages:

- - Improves functionality and lifespan of the product

- - Excellent corrosion and chemical resistance

- - Enhanced Lubricity for long-lasting friction resistance

- - Increases thermal stability and heat resistance Improves anti-galling and anti-abrasion properties

- - Excellent non-stock and release properties

- - Superb wear resistance under extreme pressure and aggressive condition

- - Thin coating that offers increased durability without affecting dimensional tolerances

- - Available in a wide range of colors and formulations

- - Pliable coating that will bend without breaking

- - Provides excellent adhesion to most metals and surfaces

CAE OFFERS CUSTOM XYLAN COATING

CAE offers high-quality, in-house Xylan@ coating services to enhance the performance properties of our fasteners. We can Xylan@ coat the following types of fasteners:

- - Bolts

- - U-Bolts

- - Custom U-Bolts

- - Custom Bent Bolts

- - Stud

- - Washers

Screws

- - Eye Bolts

- - Hex Nuts

CAE offers precision coating services for fasteners.

CAE offers high-quality, certified-engineering coating services to improve fastener performance and reliability and increase life span. We offer low friction, corrosion protection, and wear protection coatings that are tailored to your industry standards and applications. For example, we can apply a Xylan@ coating that offers low friction and corrosive resistant barrier for fastener components used in marine and salt-water applications.

Since 2010, we have been providing world-class customer service, quick turnaround times, and high-quality fastener products and components to a wide range of industries and applications. While we offer an industry-leading range of superior-quality fasteners, it is our extensive expertise and product knowledge that is the difference maker. Our team of professionals is dedicated to building a long-term customer relationship and providing valuable advice to help our clients pick the right fastener type, material, and coating for every application. Let us treat your next large batch or short run of premium fasteners with our in-house Xylan@ coating process.

Contact a member of the CAE team to find out how we can help you select the right fastener coating for your next project.

Xylan 1014

Xylan 1014 contains significantly more bonding resin which produces finishes that are harder, more abrasion resistant, glossier, and less pours. As a result it is an excellent coating for hardware and fasteners as well as machinery exposed to ice and snow which need to be protected from chemicals and corrosive agents, weathering, and abrasives. Common colors are Medium Blue (P01931E), Black (P01937E), Green (E0757A), and Yellow (E2717A).

Xylan 1070

Xylan 1070 is a low friction coating used to protect hardware, fasteners, and flanges which operate in salt water and flat spray environments. It contains additives which provide exceptional corrosion protection, compared to Xylan 1010 it offers 40% additional salt spray protection. Common colors are Black (E10211A), Dark Blue (E10212A), Yellow (E2717B), and Green (P01614E).

Xylan 1424

Xylan 1424 is a fastener coating used to prevent corrosion and improve make up torque. When applied over zinc phosphate it can withstand 1,500 hours of salt fog. This can be extended even longer if it is applied over a primer such as Xylan 1. Xylan 1424 will withstand most solvents, waters, automotive fluids and fuels up to 200*F and is impervious to new water base hydraulic fluids used in offshore oil production. This coating can be used continuously from -58F to +350F. Common colors are Brown (D11810), Yellow (D7813), Orange (D7812), Red (D6580), Green (D6583), Blue (D6584), and Black (D6586).

•KEEP RECORDS OF THE INSTALLATION, INCLUDING SUPPORT SYSTEM DRAWINGS, EQUIPMENT USED, AND ANY CHANGES OR ADJUSTMENTS MADE DURING THE INSTALLATION PROCESS. IT'S CRUCIAL TO FOLLOW THE MANUFACTURER'S GUIDELINES AND ANY INDUSTRY OR SAFETY STANDARDS RELEVANT TO YOUR SPECIFIC APPLICATION WHEN INSTALLING HOT INSULATION SUPPORT WITH CALCIUM SILICATE INSULATION. PROPER INSTALLATION ENSURES THE INSULATION SYSTEM'S EFFICIENCY AND LONGEVITY, HELPING TO CONTROL HEAT LOSS AND MAINTAIN SAFE OPERATING TEMPERATURES IN HIGH-TEMPERATURE ENVIRONMENTS.

CAE® Hot Insulation Support.

Applications with Calcium silicate insulation

HOT INSULATION SUPPORT SYSTEMS ARE ESSENTIAL FOR MAINTAINING THE INTEGRITY AND THERMAL EFFICIENCY OF INSULATION MATERIALS IN HIGH-TEMPERATURE APPLICATIONS, SUCH AS THOSE INVOLVING CALCIUM SILICATE INSULATION. PROPER SUPPORT HELPS PREVENT SAGGING OR SETTLING OF THE INSULATION MATERIAL, WHICH CAN COMPROMISE ITS EFFECTIVENESS. HERE'S HOW TO INSTALL HOT INSULATION SUPPORT FOR APPLICATIONS WITH CALCIUM SILICATE INSULATION:

1. GATHER MATERIALS AND TOOLS:

2. PLAN THE INSTALLATION:

3. PREPARE THE SURFACE:

4. INSTALL THE INSULATION0:

5. INSTALL HOT INSULATION SUPPORT:

6. SECURE THE SUPPORT SYSTEM:

7. MAINTAIN PROPER SPACING:

8. FOLLOW SAFETY PROCEDURES:

9. TEST AND INSPECT:

10. SEAL JOINTS AND SEAMS:

11. MAINTAIN DOCUMENTATION

.jpg)